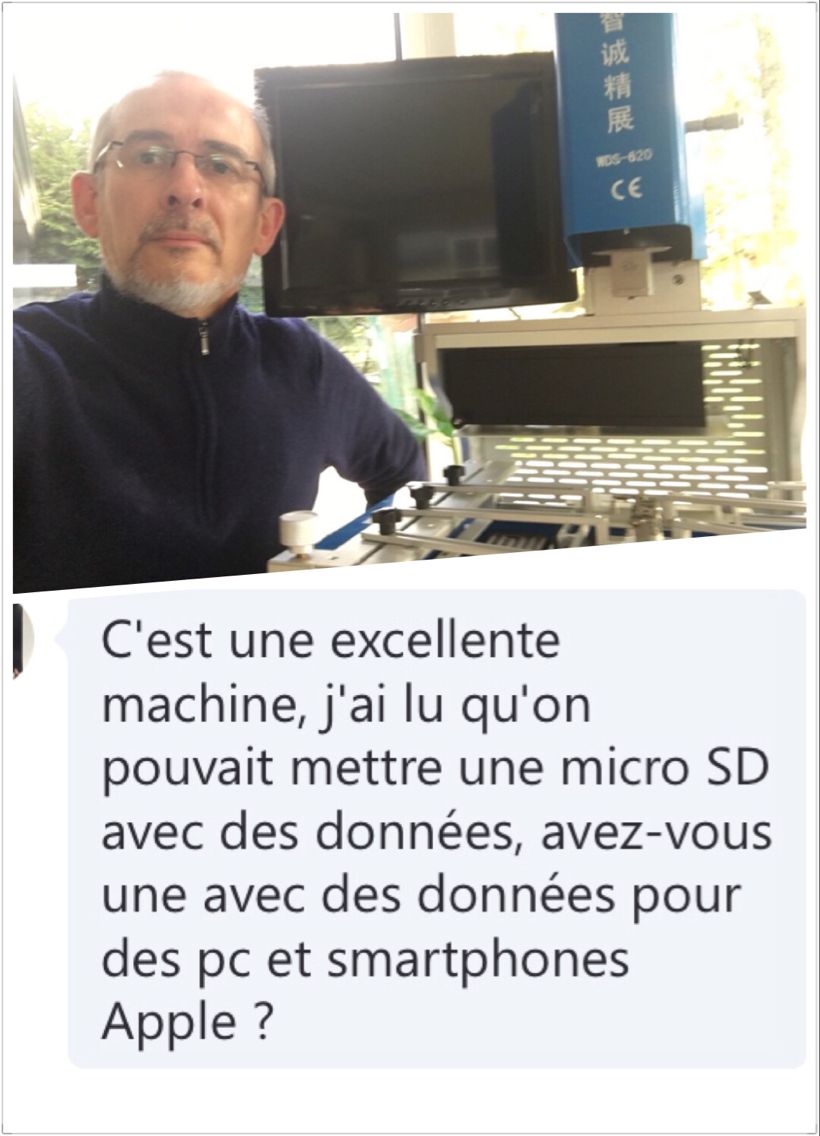

Shenzhen Wisdomshow Technology Co., Ltd. is an enterprise

integrating R & D, production, sales, trade and service. The

company is located in the west of Bao'an District, Shenzhen. Thanks

to convenient transportation conditions, such as the proximity to

Shenzhen International Airport, the coastal port and land terminal

transportation, our company has a variety of superior opportunities

for modern trade at home and abroad. Our core industry It is a BGA

rework system and peripheral auxiliary equipment, specializing in

providing SMT process solutions, providing advanced production

equipment, testing equipment, rework and excellent technical

services for domestic and foreign customers. The company's main

products are: AI, BGA hot air rework station, 3D solder paste

thickness detector, temperature curve test, AOI, parts counter, PCB

curve distribution machine, and electronic accessories. The company

appoints talents, continuously introduces high-end talents,

employees have a strong team spirit, has built an online sales

platform and communication system, and guarantees to provide

excellent after-sales service, so that the company has won good

reputation and evaluation at home and abroad. Adhering to the

business philosophy of "professionalism, innovation and integrity",

we have won the trust and support of our customers in the BGA

rework system and peripheral auxiliary equipment and consumables.

The company's products have applied for design patents, and the

products have passed CE certification, and are exported to Japan,

South Korea, North Africa, Vietnam, Southeast Asia, the Middle

East, Europe and the United States and other countries. Since the

establishment of the company, we have won the unanimous recognition

of our customers with the business philosophy of "professionalism,

integrity, excellence, customer first". In order to continuously

expand the scale of the company, we sincerely look forward to

cooperating with you.

Business scope: BGA rework station, electronic industry X-RAY

inspection equipment, visual image inspection equipment, automatic

soldering machine, sub-board machine, AOI and other automated

electronic equipment, electronic products, hardware products sales;

chip development and on-site maintenance ; R & D and sales of tin

products, electronic components, computer software and hardware

technology; sales of product masking machines, disposable

protective masks; domestic trade, import and export of goods and

technology. (Except for items that must be approved before

registration by laws, administrative regulations, and decisions of

the State Council), the licensed business items are: BGA rework

station, X-RAY inspection equipment for electronic industry, visual

image inspection equipment, fully automatic soldering machine, and

board separator , AOI and other automatic electronic equipment,

electronic products, and hardware products; production of masking

machines and disposable protective masks.